-

MADEIN MEXICOService, technology,

MADEIN MEXICOService, technology,

flexibility and precision

in engineering thermoplastic injection. -

FAMILYWith passion, commitment and

FAMILYWith passion, commitment and

experience, we are a technology

partner focused on success

and perfection. -

PRECISIONIN THERMOPLASTIC

PRECISIONIN THERMOPLASTIC

INJECTIONWe will guide you through each stage

of your project until you achieve

the success of your product.

US

With more than 27 years of experience in the thermoplastic transformation industry, we are proud to offer a comprehensive and interconnected chain of services for different sectors

SERVICE

With a comprehensive service, we help you from the concept to the production of the product, ready for marketing.

QUALITY

COPLAINSA lives quality, through a highly trained and motivated team.

US

With more than 27 years of experience in the thermoplastic transformation industry, we are proud to offer a comprehensive and interconnected chain of services for different sectors.

SERVICE

With a comprehensive service, we help you from the concept to the production of the product, ready for marketing.

QUALITY

COPLAINSA lives quality, through a highly trained and motivated team.

SERVICES

Injection molding

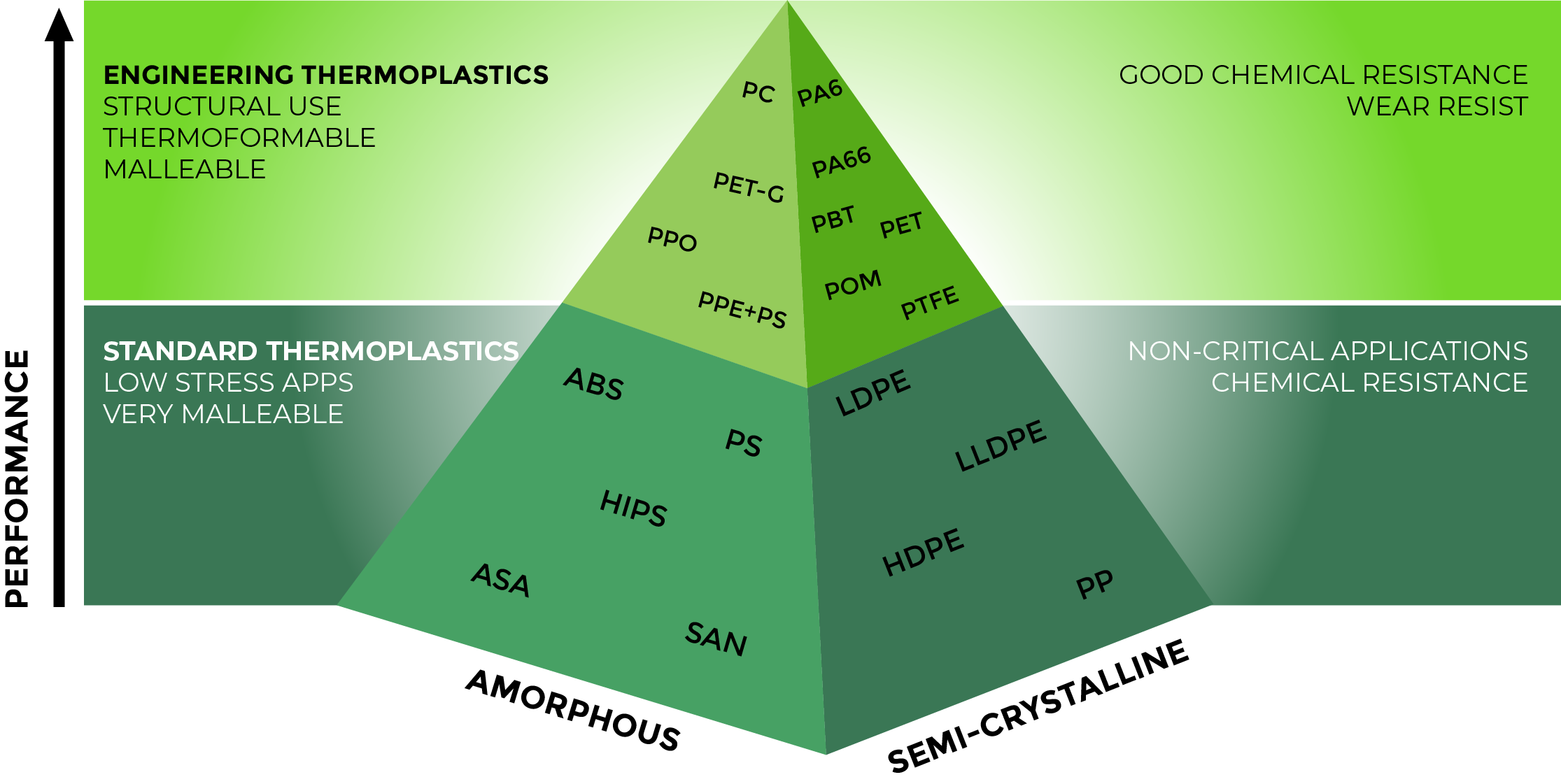

We exceed any quality expectation through the use of the highest technology and flexibility in production volumes. We specialize in injection of Engineering Thermoplastic Materials, molding of both plastic and metal components, CBA, additives, among others. Our most used resins are:

MOLD MANUFACTURING AND MAINTENANCE

With our strategic alliance with STAMPI M+B, with their expertise over 40 year in plastic injection molds. We can proudly share that we are well capable to provide support to our customers in engineering changes, preventive maintenance, corrective and soon construction in-house. Also, for bigger projects we work alongside suppliers in Portugal, Taiwan and China.

- CNC machining center

- Penetration erosion

- Flat surface grinding machine

- Conventional lathe.

- Vertical milling machine.

- ALPHA Laser 200 laser welding

- Polishing equipment

- Capacity up to 10TN.

Assembly

We have flexible assembly lines, both on-site and off-machinery, ready to adapt to your requirements, delivering parts and components ready for final use.

Finishes

We have different finishes for your projects:

- Pad printing

- Hot stamping

- Heat transfer

- Electroplating and painting, through our network of qualified suppliers

VALUE ADDED SERVICES

Distribution network

We adapt our logistics platform to your requirements, through our own distribution network and qualified suppliers, most of them with international certifications.

Quality assurance

Quality begins with us, from the first stages of design to the total satisfaction of our clients. Our quality is guaranteed with highly trained and motivated team members.

Our metrology laboratory components include:

- CMM Faro® Arm

- MITUTOYO® Optical Comparator

- Konica Minolta® Spectrophotometer

- Light cabinet

- Measurement equipment